This article discusses the advantages of using Loctite products for engineers. These products can prevent vibration-induced loosening, corrosion, and galling, and make maintenance easier. – Loctite products can help Project Engineers in a number of ways, by supplying tools and materials to face our engineering customers. We are able to assist Application Engineers by providing demonstration tools and materials that they can use while working on customer applications.

Our adhesives and sealants are used for different customer applications, including cleaning products. We have a variety of methods and applications that we use when introducing these new products to the customer. This helps us provide the most effective solutions for their needs.

Loctite products are an excellent choice for Maintenance engineers when assembling small fasteners and components. Using the same tools and same hand tool, Loctite products are designed to seal moisture, prevent loosening due to vibration and wind, and ensure repeated use.

This is especially important in screwed assemblies which require a quick check to see if everything is tight and secure. Projects can include anything from automotive to electronics, so having the right adhesive or threadlocker is essential. Loctite blue threadlockers provide a strong bond that will keep everything in place even with heavy vibration or wind. This can help make sure that every part of your assembly stays put so you don’t have to worry about it coming undone during use.

Loctite products can be used to prevent corrosion and galling, which can occur in threaded assemblies. They also help maintain clamping loads, which is important for preventing self-loosening during vibration or shock, and will help increase the reliability and service life of your machinery devices. The only efficient way to lock your threaded assemblies is with Loctite threadlockers.

These products will maintain the clamping load and prevent unplanned downtime due to loose parts or connections. It can also help increase the life of your machinery devices and minimise costs associated with maintenance. With Loctite threadlockers you can ensure that your threaded assemblies are securely held in place, preventing corrosion and self-loosening over time as well as helping to extend their life and service life.

LOCTITE ADHESIVES

The developed threadlocking adhesive eliminates vibrational loosening, ensuring maintenance engineers don’t have to re-tighten wriggle fasteners. In addition, the strength of Loctite 270 Threadlocker prevents any damage due to accidental movement of the fastener. This is especially beneficial in a production line environment where any breakdown can cause a huge amount of downtime and cost.

Types of LOCTITE THREADLOCKERS | LOCTITE RETAINING COMPOUNDS

The use of Loctite threadlocker and other threadlocking adhesives has proven to be a cost-effective way to fill gaps left by traditional fastening methods. Using Loctite branded threadlockers will provide a superior level of heat resistance, which means greater efficiency and a safer working environment. This is because customers can expect less downtime, fewer complaints and greater efficiency from the production line.

Using Loctite retaining compounds, hand tools and disassembled required joints can be sealed threads. The use of Loctite products provides easy servicing, increase torque load transfer and provide even distribution of loads stresses. This will prevent seizure of existing designs in addition to nothing when dealing with high loads.

-

LOCTITE 277 50ML | High Strength

-

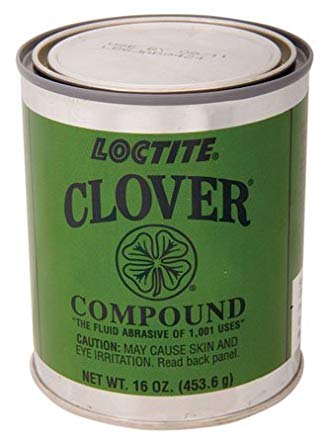

Loctite Clover Compound 180 Grit, D Grade 16 Oz

-

Loctite Clover Compound 400 Grit, 2-A Grade 16 Oz

-

LOCTITE 567 50ML Thread Sealant Low Strength

-

LOCTITE SF 7063 PARTS CLEANER ( DEGREASER ) 400ML

-

LOCTITE LB 8008 C5-A COPPER ANTISEIZE LUBRICANT 1LB

-

Loctite Clover Compound 120 Grit, E Grade 16 Oz

-

Loctite Clover Compound 320 Grit, 1-A Grade 16 Oz

-

LOCTITE 601 50ML